MINI FLOW

The hoods of the MINI FLOW series have been developed for the protection of operators, products and the environment with the criterion of the typical vertical Laminar Flow hoods (Class II non-Biohazard) having reduced dimensions.

The air decontaminated by the absolute filter flows with laminar flow over the work area, crosses the work surface, mixes with the outside air, which enters the cabin through the front opening, in the front slotted area of the work surface. The contaminated air is sucked by the fan placed in the upper part of the cabin and conveyed to the plenum: here about 70% is sent again to the work area after absolute filtration while the remaining 30% is simply expelled to the outside (mod. FLV ), or exploded after absolute filtration (mod. FLV / H) or absolute filtration and molecular filtration on carbofiltro (mod.FLV / HC).

The quantity of expelled air is therefore reintegrated with an equal amount of ambient air sucked through the front opening, generating an operator protection barrier. They are versatile hoods and, thanks to their small dimensions, can be easily placed where required.

Technical features

- External carpentry in steel sheet painted with oven-spiked polyepoxide powder

- Double rear suction bottom to even out the horizontal air flow

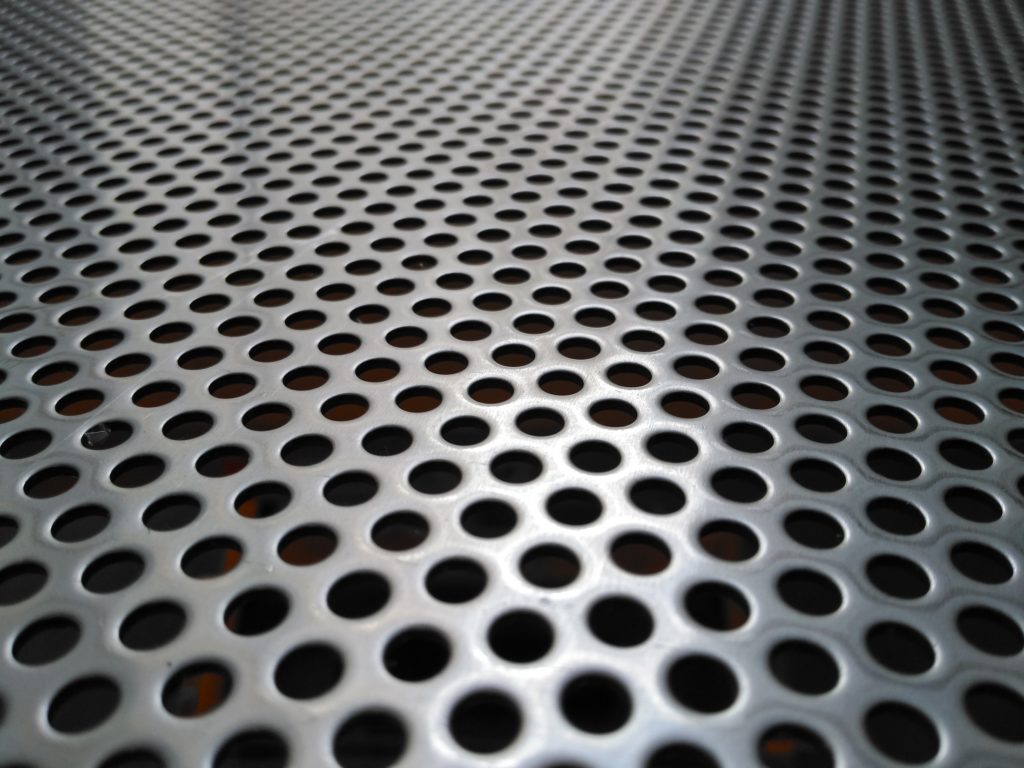

- Drilled worktop in AISI 304 stainless steel divided into two sections that can be easily removed for accurate cleaning

- Liquid collection tank underneath the work surface in painted sheet metal

- Front tempered glass (5 mm thick) opening with a compass, with the possibility of locking in the fully open position

- Front opening height: min 200 mm - max 350 mm

- Thermally protected fan motor

- Exhaust collar (diameter: 150 mm) for possible conveying outside the expelled air through PVC pipe

- Fluorescent lamp in the area outside the working chamber (13 W power)

- Work area lighting:> 700 lux

- Germicidal UVC lamp (optional): power 15 W

- Front-panel control panel with soft-touch membrane keyboard

- High quality electronic card managed by a microprocessor

- Digital electronic hourmeter for machine activity and UV germicidal lamp operation (if installed)

- Interlocking fluorescent lamp / UV lamp (optional)

- Countdown timer UVC lamp can be set by the customer with auto-off at the end of the cycle

- Visual pre-alarm on display for exceeding the maximum period for replacing the installed filter (resettable)

- Capacity: 350 m3 / h

- Average air speed: 0.4 m / sec

- Class of work: 100 (according to ISO5)

- Possibility of manual adjustment of the air flow by the operator directly on the keyboard for:

* modify the standard calibration carried out at the factory for particular working needs

* increase the voltage gradually to the fan motor to avoid the progressive clogging of the prefilters and any absolute filters, if installed, up to the maximum limit

- Noise level: <58 dB (A)

- Installed power: 250 W

- Power supply: 230V 50 Hz

- External dimensions: 800 x 580 x 940 mm (W x D x h)

- Useful internal dimensions: 795 x 500 x 575 mm (W x D x h)

- Net weight:

° mini Flow FLV: 70 kg

° mini Flow FLV_H: 73 kg

° mini Flow FLV_HC: 78 kg

- Compliance: built in compliance with the Standards

ISO 5 (formerly Federal Standard 209D)

Italian Electrotechnical Committee (CEI 66.5)

CEI 62.25 for class 1 fixtures fixed installation

UNI-CIG