GP FLOW

Simple and small machine, designed for tight spaces and created for the protection of the product, the operator and the environment, the GP FLOW hood allows pollutants to be removed directly from the source, thanks to the vertical laminar flow on the worktop of sterile air. The laminar flow is generated by two internal radial fan motors, controlled by the operator, which can vary the speed at will using the luminous switch and the control variator located on the keyboard.

Due to its construction, it is clearly not a Biohazard hood but still a small vertical laminar flow hood suitable for handling substances with low biological risk. The air decontaminated by the absolute downflow filter descends with laminar flow on the work area, crosses the floor, mixes with the outside air, which enters the cabin through the front opening, in the front area of the work surface. The contaminated air is sucked by the fan motors placed in the upper part of the cabin and for about 70% it is sent again to the work area after absolute filtration while the remaining 30% is simply expelled to the outside (in the GP Flow Standard model), or exploded after absolute filtration with H14 filters (in the Plus and GP_H standard models). The quantity of expelled air is reintegrated with an equal quantity of ambient air sucked through the front opening, generating a barrier of protection for the operator.

Technical features

- External carpentry: in carbon steel sheet, thickness 10/10, epoxy powder coating (durability over time, chemical resistance).

- Working chamber: - Rear bottom: in AISI 304 stainless steel with satin scotch-brite finish, it can accommodate electric sockets and / or gas taps (optional) - Side walls: in glass (thickness 4 mm) - Front panel: in tempered glass (5 mm thick), can be opened by sliding vertically sliding manually, positioned by the customer at any height

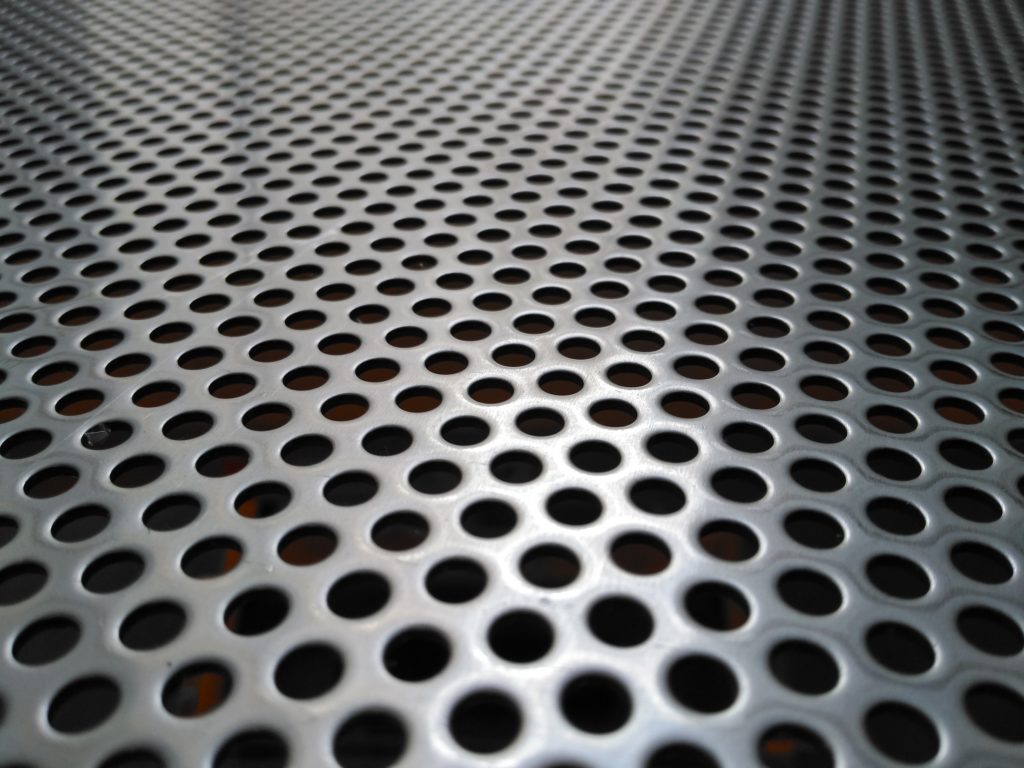

- Worktop: in AISI 304 stainless steel with holes and aspirated from below, divided into two removable segments for cleaning

- Fan motors: 2 internal radial fans (electrical protection degree IP44) with 70% air distribution in downflow and 30% in exhaust

° Standard models: manual suction adjustment

° Plus models: automatic suction adjustment

- Average LAF speed: 0.40 m / s

- Average barrier speed: 0.40 m / s modifiable by the user

- Filters: absolute HEPA in class H14 according to EN 1822 (efficiency 99.995% MPPS)

- Noise level: <58 dBA

- Useful dimensions: 690 x 500 x 400 mm (L x W x H)

- External dimensions: 700 x 550 x 700 mm (L x W x H)

- Power supply: 220/240 V - 50 Hz

- Weight: 50 Kg approx

ADDITIONAL TECHNICAL FEATURES ONLY "PLUS" MODELS:

- Lighting:> 700 lux with 13 W fluorescent lamp

- Possibility of ducting outside the air expelled from the installation room by means of a collar with flange diam. 150 mm (optional), vacuum motor excluded

- Digital display with real-time reading of the air speed on the front opening (in m / sec)

- Countdown UV lamp operation timer settable by the customer with auto-off at the end of the cycle

- New generation microprocessor controlled and controlled electronic card with alphanumeric display

- Automatic adjustment of front air speed able to compensate:

- continuously changes in the front glass opening

- the progressive clogging of the absolute filters

- the presence of the operator in front of the cabin, reducing turbulence in the work areas

- Digital hour meter for motor operation

- Control panel with soft-touch polycarbonate keyboard and a high-tech electronic board with the following functions: - general 0/1 luminous switch - audible and visual alarms on display for: - insufficient speed - exceeding maximum period for replacement of filters (resettable) - maximum period for replacing the UVC lamp, if installed (resettable). - buttons for:

- operation of fan motors - ignition of fluorescent lamp - activation of germicidal lamp UVC - internal electrical socket power supply (possibly present)

CONFORMITY '

The hoods are built in accordance with:

ISO 5 (formerly Federal Standard 209D)

European Standard EN 1822

Italian Electrotechnical Committee (CEI 66.5)

CEI 62.25 standards for class I appliances, fixed installation

UNI-CIG regulation