BIO VE

The BIO ACTIVA VE hood has been developed for the global protection of operator, product and environment during the manipulation of pathogenic material.

The biohazard hood, in Class II type A1 and A2 (ex A and B3) has a front opening with air inlet from outside to inside, vertical laminar air flow inside the cabin and HEPA filter in Exit.

As required by the regulations in force the air decontaminated by the absolute filter descends vertically with laminar flow in Class 100 on the work area and crosses the plane. The contaminated air is sucked by the fan placed in the upper part of the cabin and conveyed in a plenum: here about 70% is sent again to the work area with absolute filtration while the remaining 30% is expelled to the outside (thanks to the Plus model to a second fan motor that is absent in the Standard model), after absolute filtration. The mass of air sucked in and recycled by the main fan keeps the recovery channel in negative pressure. The expelled air is reintegrated with an equal amount of ambient air sucked in through the front opening, creating a front insulation barrier in the area of access to the work area.

The Bio Activa VE 120 - 150 and 180 models are TUV certified according to the UNI EN 12469 standard (certificate No. ZI 10 09 62765 004 and No. Z1 10 09 62765 003)

Technical features

- External carpentry in steel sheet (thickness 12/10), polyepoxide powder painting

- Work chamber totally in AISI 304 stainless steel with scotch-brite finish

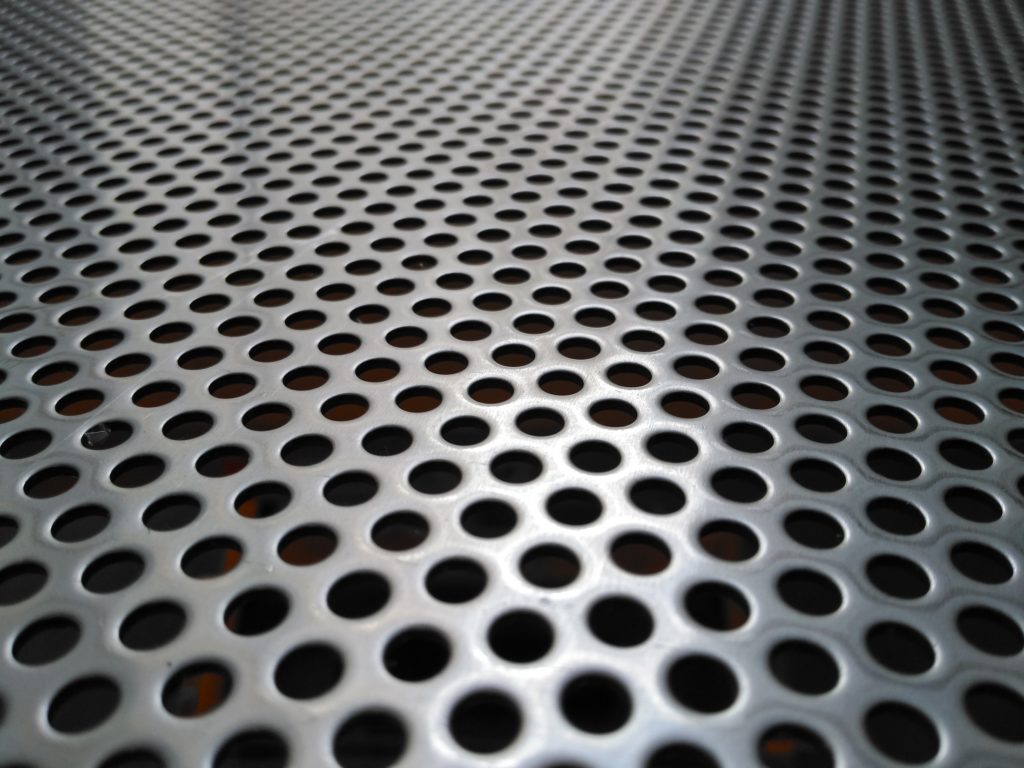

- Perforated worktop in AISI 304 stainless steel, scotch-brite finish, divided into four segments that can be easily removed and sterilized. Large liquid collection tank underneath the steel worktop

- Front protection tempered shatterproof glass (6 mm thick) opening with vertical motorized latch, with acoustic alarm of incorrect operating condition, equipped with glass support gasket in total closure. The shatterproof tempered front glass has vertical sliding opening and closing with motorized movement from the pushbutton panel on the control panel. The glass can also be fully opened to over 90 ° with a tilting mechanism for cleaning the interior and for introducing bulky material.

- Electronically controlled motorized fan able to compensate the load losses due to the progressive clogging of the absolute filters

° STANDARD model: 1 motor fan

° PLUS model: 2 fan motors

- Possibility of ducting the expelled air to the outside if required by the installation room by means of an optional collar of 250 mm in diameter (only for the PLUS model)

- Dynamic sealing plenum

- Two absolute filters (HEPA), removable from the front and top, with an efficiency greater than 99.995% MPPS (ex 99.999% on particles with a diameter equal to or greater than 0.3 microns), complying with all the regulations

- Sockets for DOP flow test and exhaust tests

- Automatic adjustment of downflow air speed and exhaust air (front barrier)

- Expelled air flow rate: 400 cubic meters / hour

- Noise level: <60 dBA

- Average LAF speed:> 0.40 m / sec (modifiable by the customer)

- Average barrier speed:> 0.40 m / sec (modifiable by the customer)

- Luminous intensity on the work surface:> 800 lux

- Power supply: 230 V; 50 Hz

- External dimensions (except support):

° mod. 90: 980 x 795 x 1310 mm (l x px h)

° mod. 120: 1285 x 795 x 1310 mm (l x px h)

° mod. 150: 1465 x 795 x 1310 mm (l x px h)

° mod. 180: 1890 x 795 x 1310 mm (l x px h)

- Useful internal dimensions:

° mod. 90: 915 x 690 x 640 mm (l x px h)

° mod. 120: 1220 x 690 x 640 mm (l x px h)

° mod. 150: 1400 x 690 x 640 mm (l x px h)

° mod. 180: 1825 x 690 x 640 mm (l x px h)

- Net weight:

° mod. 90: 184 kg

° mod. 120: 240 kg

° mod. 150: 245 kg

° mod. 180: 290 kg

CONTROL PANEL

On the control panel, which encloses the electronic card controlled by a new generation microprocessor, there are:

- General O / I selector with key control

- Membrane keyboard (soft touch) with antistatic protection

- Digital display with real-time reading of vertical laminar flow and front barrier speed, expressed in meters / second. New microprocessor-controlled electronic board, with Lcd-type digital display for real-time display of all operating parameters, and various alarms for operator safety.

- U.V. lamp operation timer a countdown set by the customer with auto-off at the end of the cycle

- Digital electronic hour meter for general machine operation

- Digital electronic hour meter for U.V. (if installed)

- Pre-alarm of maximum time limit of use of installed absolute filters, with indication of need for next replacement

- Acoustic and visual alarm for:

- front window in incorrect position

- filter clogging

- faulty operation of the motorized fan (s)

- downflow anomalies and anomalies due to exhaust (frontal barrier)

- reached limit of use of the installed filters

- reached UV lamp usage limit

- Buttons for:

- activation of motor-fan / s

- UP / DOWN electric window

- activation of a safety solenoid valve (if installed) on a gas tap

- switching on fluorescent lamp and UVC lamp (if installed) interlocked with each other

- power supply to the internal electrical outlet

- Emergency button to increase the speed of the expulsion air flow (operator protection barrier)

CONFORMITY '

° STANDARD model

Safety cabin against biological hazards (BIOHAZARD), with working area protected by vertical laminar flow in class 100 (ISO 5, former Federal Std 209 E), bench version, classified as class II type A1 and therefore suitable for handling pathogens low / medium biological risk.

Built in accordance with:

European Standard EN 1822

Italian Electrotechnical Committee (CEI 66.5)

UNI-CIG regulation

° PLUS model

Safety cabin against biological hazards (BIOHAZARD), with working area protected by vertical laminar flow in class 100 (ISO 5, former Federal Std 209 E), bench version, classified as class II type A1 / A2 and therefore suitable for handling pathogens with low / medium biological risk.

Built in accordance with:

European Standard EN 1822

British Standard Institution (BSI 5726)

Deutsches Institute fuer Normueng (DIN 12950)

Italian Electrotechnical Committee (CEI 66.5)

UNI-CIG regulation

Both models also comply with the recommendations expressed by the WHO and the National Commission for the fight against AIDS of the Ministry of Health on the safety of health workers.